“The Tomorrowland attractions have been designed to give you an opportunity to participate in adventures that are a living blueprint of our future.” – Walt Disney.

LITS Student Services has always stood at the intersection of students and technology. Whether fixing devices students bring to campus or offering a place for them experience something new, Student Services plays an integral role in the experience students have with technology while at Emory.

Student Services built its reputation on things like the Student Technology Support office (formerly Cleanroom if you have been around long enough) and the Computing Center at Cox Hall, often lauded for its focus on flexibility, comfort and innovative design. While providing this support, Student Services also pushes the envelope to incorporate new technologies to help expose students to tools they might not have otherwise. In the Student Services research and development (R&D) labs we have been exploring some new ideas we think will excite faculty, staff and students.

3D printing has been around since the 1980’s. It has been used in the manufacturing and development of goods, big and small. Only in the last few years has it reached a point where the average consumer has become truly aware of this technology and started to get their own hands on it.

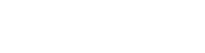

Many brands have appeared out of this new revolution of production, such as Makerbot, RepRap, and Solidoodle. By bringing this technology to a “prosumer” level of affordability, rapid prototyping becomes an option for a wide swath of users. The Student Services R&D labs brought some of this technology to campus. We recently acquired a Makerbot Replicator 3D printer; allowing us (using a PLA bases plastic) to print physical objects people designed on their computers.

Student Services has only begun to learn the extent of what we can do with this new technology. We printed a couple dozen products, ranging from 30mm WWII tank replicas, to an 8-inch replica of the T-800’s head (from the popular Terminator movie series), and a 14-inch replica of Megaman’s helmet (video game character from the Megaman series). Each of these objects, and even more unlisted, allow us to observe and learn about printing certain textures, shapes, and densities.

We plan to begin collaborating with students and faculty soon in hopes of incorporating this technology into class course work and extracurricular activities. We see potential for groups on campus printing replicas of artifacts found halfway across the globe for an anthropology class, a knee joint when studying osteology or perhaps a robot chassis for a programing class. The possibilities are wide and varied.

Another item that we recently added to our R&D library is the Google Glass…